Steel platform direct fasteners are essential components designed for efficient and secure attachment of steel platforms, offering a reliable solution in construction and industrial applications. These direct fasteners are engineered to simplify the installation process, reducing labor time while ensuring a strong, lasting connection. With their high load-bearing capacity and corrosion-resistant materials, steel platform direct fasteners are ideal for both indoor and outdoor environments.

Manufactured for precision and durability, steel platform direct fasteners are compatible with a wide range of structural steels, making them a versatile choice for projects that demand performance and safety. Whether used in commercial buildings, warehouses, or mezzanine systems, these fasteners provide a dependable method for connecting steel components directly without the need for pre-drilling or complex tools.

The streamlined installation of steel platform direct fasteners not only enhances job site efficiency but also minimizes potential alignment errors. Their design allows for secure anchoring under high-stress conditions, maintaining structural integrity even in challenging environments. These fasteners are especially beneficial where quick setup and robust results are priorities.

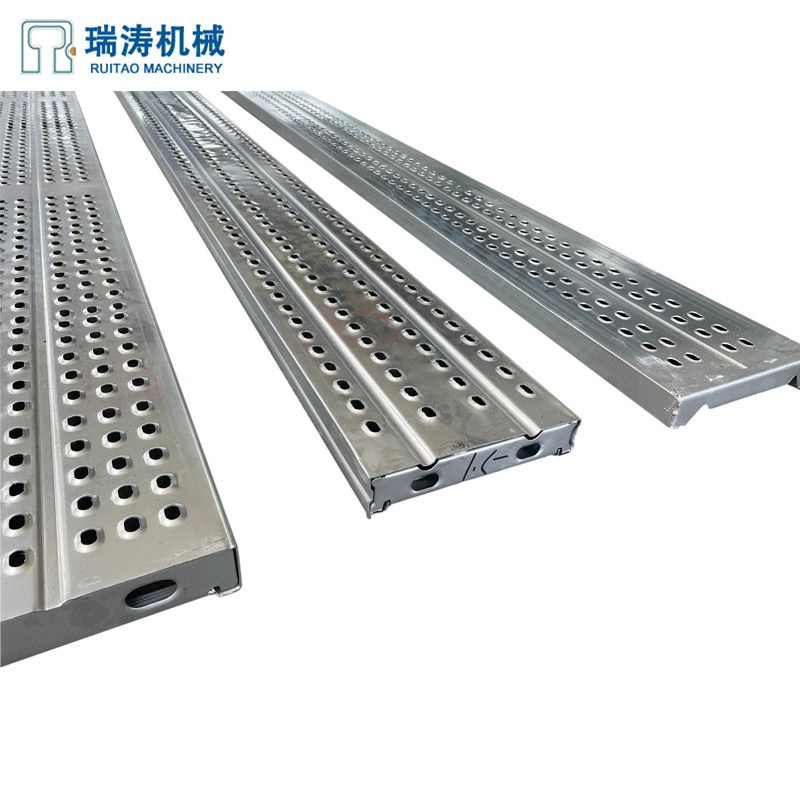

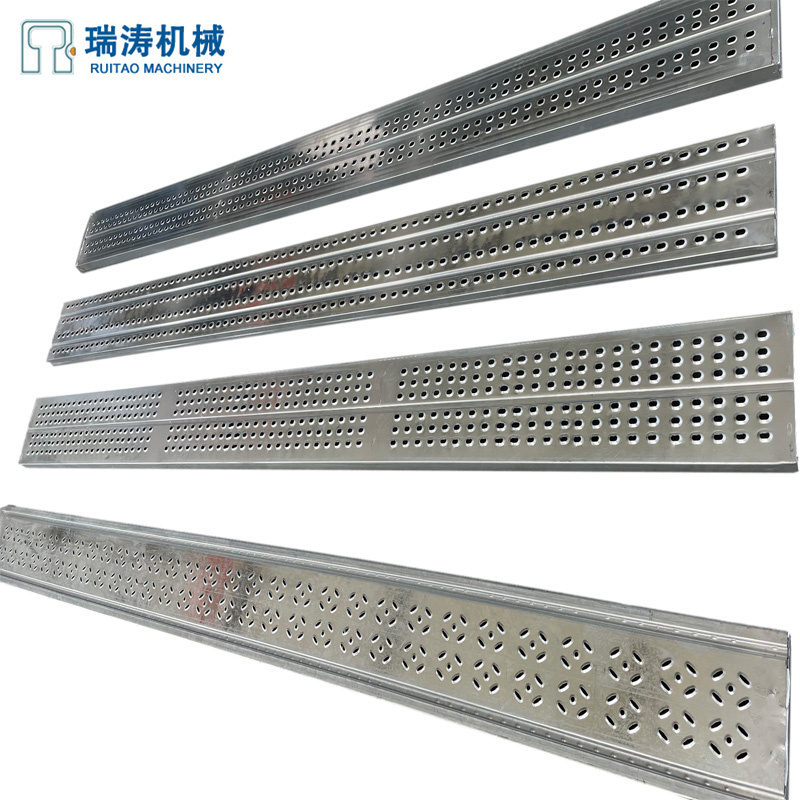

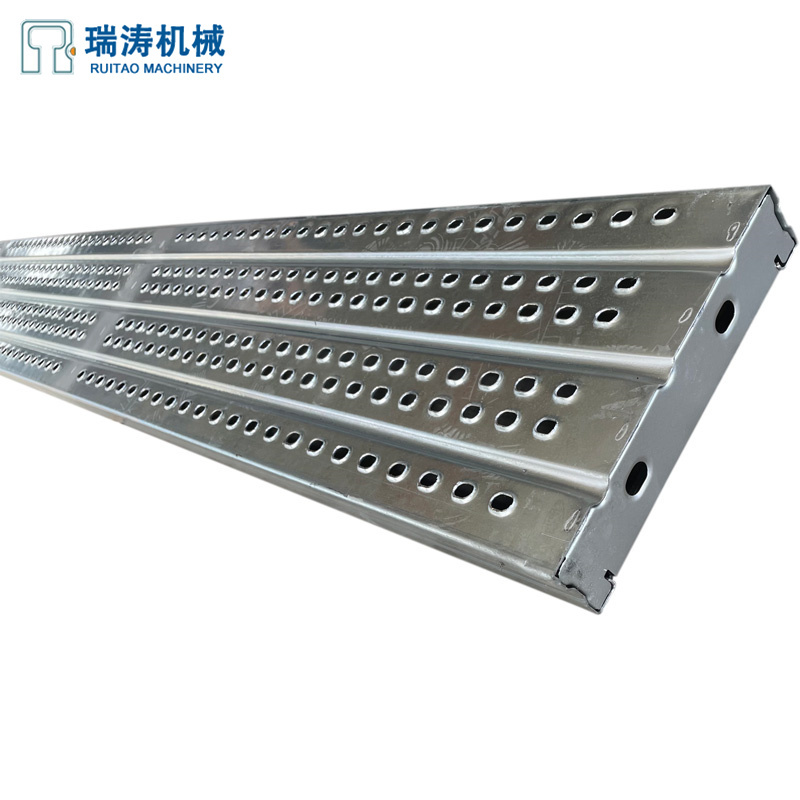

The company has been specializing in the design and production of steel springboards, hot-dip galvanized steel springboards, and kickboards for many years. There are now one universal type: 240 × 45, 240 × 65, 250 × 50, 300 × 55, etc; 2、 Fully enclosed anti accumulation sand mold: 8 fully automatic steel springboard processing production lines including 230 × 45, 240 × 45, 240 × 50, 250 × 50, 300 × 50, 300 × 55, etc. The annual sales revenue is 120 million yuan, and there are currently 128 employees, including 1 senior engineer, 3 engineers, 6 assistant engineers, and 16 other engineering and technical personnel. Having fixed assets of over 20 million yuan and free flowing funds of over 20 million yuan. There are currently eight steel springboard production and forming workshops, four semi-finished welding workshops, and two packaging workshops. Over the past few years, our company has relied on good credit and the principle of putting people first, relying on technology and scientific institutions, continuously strengthening technological transformation and innovation, and upgrading our products to meet the needs of different customers.