How Quality Hook-Style Steel Jumping Platforms Improve Worksite Safety

Table of Contents

1. Introduction to Hook-Style Steel Jumping Platforms

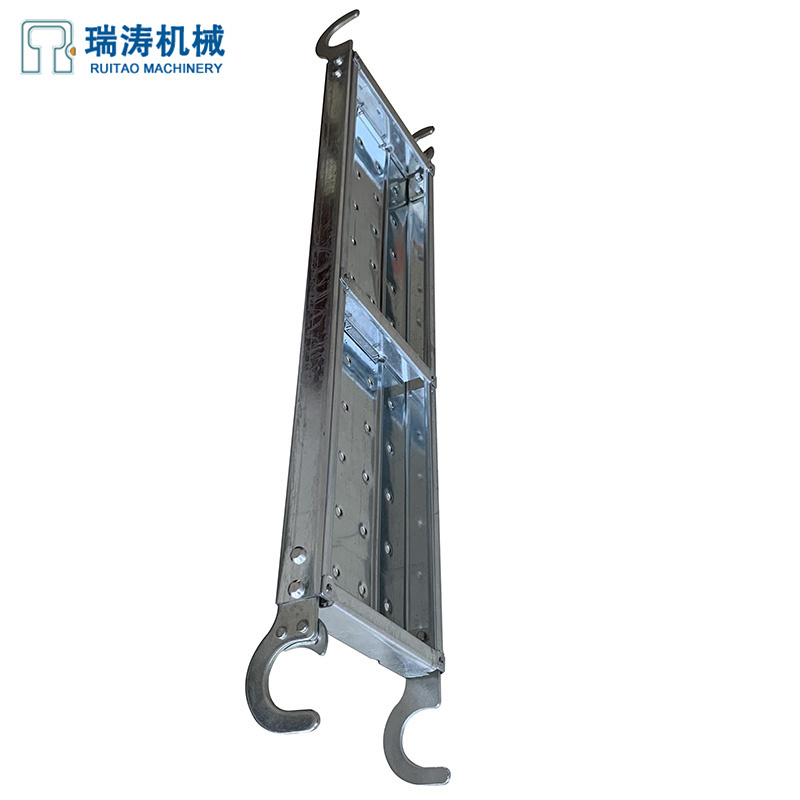

In the construction industry, ensuring the safety of workers is paramount. One innovative solution that has gained traction is the **hook-style steel jumping platform**. These platforms offer a stable and secure working surface, allowing workers to perform their tasks efficiently while significantly reducing the risk of accidents.

Hook-style steel jumping platforms are designed to provide a reliable, elevated work area that can be easily adjusted and secured. By understanding their construction and design, we can appreciate how they contribute to improved safety on worksites.

2. The Importance of Worksite Safety in Construction

The construction sector is inherently risky, with a variety of hazards ranging from falls, equipment mishandling, to environmental dangers. According to OSHA (Occupational Safety and Health Administration), falls account for a significant percentage of construction-related fatalities. Therefore, implementing safety measures is not just a regulatory requirement; it is essential for the well-being of all personnel on site.

Quality hook-style steel jumping platforms play a crucial role in mitigating risks associated with working at heights. By providing a secure and adaptable platform, these structures help prevent falls, ensuring that workers can focus on their tasks without the constant worry of workplace hazards.

When selecting hook-style steel jumping platforms, it’s essential to look for specific features that ensure safety and durability. Key features to consider include:

3.1. Sturdy Construction

Quality platforms are crafted from high-grade steel, ensuring they can withstand heavy loads and adverse weather conditions. This strength is vital for maintaining a safe working environment.

3.2. Secure Hook Mechanism

The hook mechanism must be reliable, allowing for easy attachment and detachment while ensuring stability. A well-designed hook system minimizes the risk of accidental disengagement.

3.3. Adjustable Height

The ability to adjust the height of the platform allows workers to access various levels safely, accommodating different building structures and project requirements.

3.4. Non-Slip Surface

A non-slip surface is crucial for preventing slips and falls. High-quality platforms often incorporate textured surfaces or additional grip materials for enhanced safety.

3.5. Lightweight and Portable Design

Ease of transport and setup is essential for efficiency on construction sites. A well-designed jumping platform should be lightweight yet durable, facilitating quick relocation as project needs evolve.

4. Benefits of Using Hook-Style Jumping Platforms for Safety

Integrating hook-style steel jumping platforms into your construction workflow has numerous safety benefits, including:

4.1. Enhanced Stability

The secure design of hook-style platforms provides a stable work surface, minimizing the risk of wobbling or shifting during use.

4.2. Reduced Risk of Falls

With a properly installed platform, the likelihood of falls from heights decreases significantly, protecting workers from serious injuries.

4.3. Increased Efficiency

Workers can perform their tasks more efficiently when they feel safe and secure. This efficiency leads to improved productivity and project timelines.

4.4. Compliance with Safety Regulations

Using quality steel jumping platforms helps companies comply with safety standards and regulations, reducing the risk of legal complications and fines.

4.5. Long-Term Cost Savings

Investing in high-quality platforms can result in long-term savings by preventing accidents and injuries, which can lead to costly medical expenses and lost work time.

5. Comparison with Other Types of Jumping Platforms

While there are various types of jumping platforms available, hook-style steel platforms stand out for several reasons:

5.1. Traditional Wooden Platforms

Wooden platforms can deteriorate over time, leading to instability and increased risk of accidents. In contrast, steel platforms offer superior durability and strength.

5.2. Aluminum Platforms

Aluminum platforms are lightweight but may lack the strength required for heavy-duty applications. Steel platforms provide a more robust solution for demanding work environments.

5.3. Other Steel Platforms

Not all steel platforms are designed with hooks. Hook-style platforms offer unique benefits, such as quick setup and secure attachment, that enhance safety compared to standard steel options.

6. Best Practices for Using Steel Jumping Platforms

To maximize the safety benefits of hook-style steel jumping platforms, adhering to best practices is crucial:

6.1. Proper Installation

Ensure that the platform is installed according to the manufacturer's specifications. Regularly inspect the hooks and connections to guarantee secure attachment.

6.2. Training and Education

Provide comprehensive training for all workers on how to use jumping platforms safely. This training should include proper loading techniques and emergency procedures.

6.3. Regular Inspections

Conduct regular inspections of the platforms for wear and damage. Replace any components that show signs of deterioration promptly.

6.4. Use Personal Protective Equipment (PPE)

Even with secure platforms, workers should always wear appropriate PPE, including helmets, harnesses, and slip-resistant footwear.

6.5. Communicate Effectively

Establish clear lines of communication among team members while working on platforms. Use signals and designated spotters to ensure everyone is aware of their surroundings.

7. Maintenance Tips for Sustaining Platform Quality

Proper maintenance can extend the lifespan of hook-style steel jumping platforms and ensure they remain safe for use:

7.1. Clean Regularly

Dirt, debris, and moisture can affect the grip and stability of platforms. Regular cleaning helps maintain a safe working surface.

7.2. Inspect for Rust and Corrosion

Inspect platforms for signs of rust or corrosion, especially in outdoor environments. Addressing these issues promptly can prevent structural weaknesses.

7.3. Lubricate Moving Parts

If the platform has movable components, ensure they are properly lubricated to maintain smooth operation and prevent wear.

7.4. Store Properly

When not in use, store platforms in a dry, sheltered area to protect them from weather elements that could cause damage.

7.5. Keep Documentation

Maintain records of inspections and maintenance activities. This documentation is vital for compliance and helps identify patterns or recurring issues.

8. Case Studies: Success Stories from the Field

To understand the real-world impact of hook-style steel jumping platforms, let's explore some success stories from various construction sites:

8.1. Project A: High-Rise Construction

In a high-rise construction project, the implementation of hook-style jumping platforms allowed for a 30% reduction in fall-related incidents. Workers reported feeling more secure, which directly contributed to increased productivity.

8.2. Project B: Bridge Renovation

During a bridge renovation project, hook-style platforms provided access to hard-to-reach areas. The project completed ahead of schedule, with no recorded safety incidents, thanks to the reliability of the platforms.

8.3. Project C: Industrial Facility Construction

At an industrial facility construction site, using high-quality jumping platforms resulted in significant cost savings. The reduction in workplace accidents helped lower insurance premiums and avoid costly downtime.

9. Frequently Asked Questions

9.1. What are hook-style steel jumping platforms?

Hook-style steel jumping platforms are elevated work surfaces designed with a secure hook mechanism for attachment, providing stability and safety for workers.

9.2. How do these platforms improve safety?

These platforms reduce the risk of falls and accidents by offering a secure work area, allowing workers to perform tasks efficiently and safely.

9.3. What materials are used in their construction?

High-quality hook-style platforms are typically made from durable steel to ensure strength and longevity, often featuring non-slip surfaces.

9.4. Are there any weight limits for these platforms?

Yes, each platform is designed with specific weight limits. Always refer to the manufacturer's guidelines to ensure compliance with safety standards.

9.5. How often should I inspect the platforms?

Regular inspections should be conducted at least once a month or more frequently depending on usage and environmental conditions. Always replace any damaged components immediately.

10. Conclusion

The implementation of quality hook-style steel jumping platforms is a pivotal factor in enhancing safety on construction sites. Their sturdy construction, secure mechanisms, and ease of use significantly reduce the risk of workplace accidents, allowing workers to perform their jobs with confidence. By adhering to best practices, conducting regular maintenance, and learning from successful case studies, construction companies can ensure a safer working environment while improving overall productivity. Investing in high-quality platforms not only fulfills safety regulations but also contributes to the well-being of all personnel involved in construction projects.